2019 China New Design 20 Years Fiber Optic Manufacturer Supply High Quality Marine Cable

We normally continually offer you quite possibly the most conscientious buyer services, as well as the widest variety of designs and styles with finest materials. These efforts include the availability of customized designs with speed and dispatch for 2019 China New Design 20 Years Fiber Optic Manufacturer Supply High Quality Marine Cable, Our merchandise are new and old prospects consistent recognition and trust. We welcome new and old prospects to call us for long term company relations, common progress. Let’s speeding while in the dark!

We normally continually offer you quite possibly the most conscientious buyer services, as well as the widest variety of designs and styles with finest materials. These efforts include the availability of customized designs with speed and dispatch for HDMI Cable and Fiber Optic Cable, Now we have been making our goods for more than 20 years . Mainly do wholesale , so now we have the most competitive price , but highest quality. For the past years , we got very good feedbacks , not only because we supply good merchandise , but also because of our good after-sale service . We have been here waiting for you for your inquiry.

Overview

Metal Expansion Joint

Metal expansion joint is a kind of compensator made of metal like stainless steel 316L and 254 etc. It can expand and contract along the axis of the pipeline, and also allows a small amount of bending. Axial bellows expansion joints are used on pipelines for axial length compensation. In order to prevent exceeding the allowable compensation amount, protective pull rods or protective rings are arranged at both ends of the corrugated pipe, and guide brackets are arranged on the two ends of the pipe connected to it. In addition, there are corner and lateral expansion joints, which can be used to compensate for the corner and lateral deformation of the pipeline. The advantage of this type of expansion joint is to save space, save materials, and facilitate standardization and mass production.

Our products are widely applied on the EGCS system, 254 material is highly recommended as good corrosion resistant performance in acid environment. Thanks to the good process and quality control, our products are much durable and gain a lot of favorable comments from shipowners and shipyards.

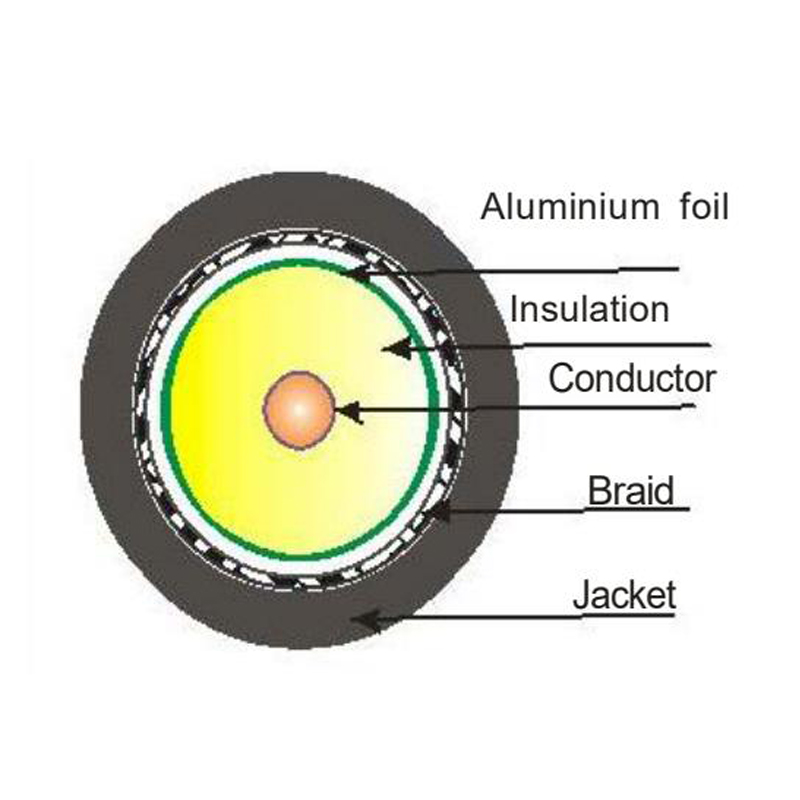

| Temperature Range: | -30°C~70°C |

| Halogen acid gas, Degree of acidity of gases: | IEC 60754-1/2 |

| Jacket, Insulation material: | IEC 60092-360 |

| Smoke Emission: | IEC 61034-1/2 |

| Flame Retardant: | IEC 60332-3-22 |

| UV-resistant: | UL 1581 |

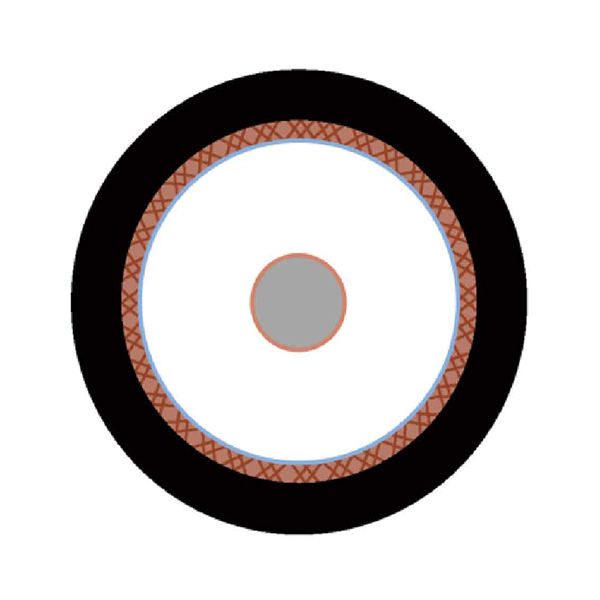

| Inner Conductor DC resistance: | ≤102 Ω/km |

| Outer Conductor DC resistance: | ≤9.0 Ω/km |

| Capacity: | 52 ± 5 pF/m |

| Characteristic Impedance200MHz: | 75 ± 3 Ω |

| Maximum attenuation is 3% higher Nominal attenuation | ||||||||||||||

| Frequency (MHz): | 5 | 55 | 211 | 300 | 500 | 600 | 870 | 1000 | 1300 | 1450 | 1700 | 2000 | 2250 | 3000 |

| Attenuation dB/100 m (Nom.): | 1.95 | 5.25 | 10.0 | 11.64 | 15.29 | 16.73 | 20.04 | 22.0 | 25.0 | 26.8 | 29.5 | 32.0 | 34.4 | 40.4 |

| Return Loss | ||||||||||||||

| Frequency (MHz): | 30~1000 | 1000~3000 | ||||||||||||

| Return Loss (dB): | ≥20 | ≥15 | ||||||||||||