2019 Latest Design Fiber Optic Accessories Cable Bundle 201 304 316 Stainless Steel Banding Clamping Buckle/Clips

We pursue the management tenet of “Quality is superior, Service is supreme, Reputation is first”, and will sincerely create and share success with all clients for 2019 Latest Design Fiber Optic Accessories Cable Bundle 201 304 316 Stainless Steel Banding Clamping Buckle/Clips, Any interest, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

We pursue the management tenet of “Quality is superior, Service is supreme, Reputation is first”, and will sincerely create and share success with all clients for China Insulation Materials and 304 316 Banding, By integrating manufacturing with foreign trade sectors, we can provide total customer solutions by guaranteeing the delivery of right goods to the right place at the right time, which is supported by our abundant experiences, powerful production capability, consistent quality, diversified items and the control of the industry trend as well as our maturity before and after sales services. We’d like to share our ideas with you and welcome your comments and questions.

For used in control systems for analogue or digital signal transmission. suitable for outdoor use at

temperature range from -52℃ to +80℃.

We pursue the management tenet of “Quality is superior, Service is supreme, Reputation is first”, and will sincerely create and share success with all clients for 2019 Latest Design Fiber Optic Accessories Cable Bundle 201 304 316 Stainless Steel Banding Clamping Buckle/Clips, Any interest, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

2019 Latest Design China Insulation Materials and 304 316 Banding, By integrating manufacturing with foreign trade sectors, we can provide total customer solutions by guaranteeing the delivery of right goods to the right place at the right time, which is supported by our abundant experiences, powerful production capability, consistent quality, diversified items and the control of the industry trend as well as our maturity before and after sales services. We’d like to share our ideas with you and welcome your comments and questions.

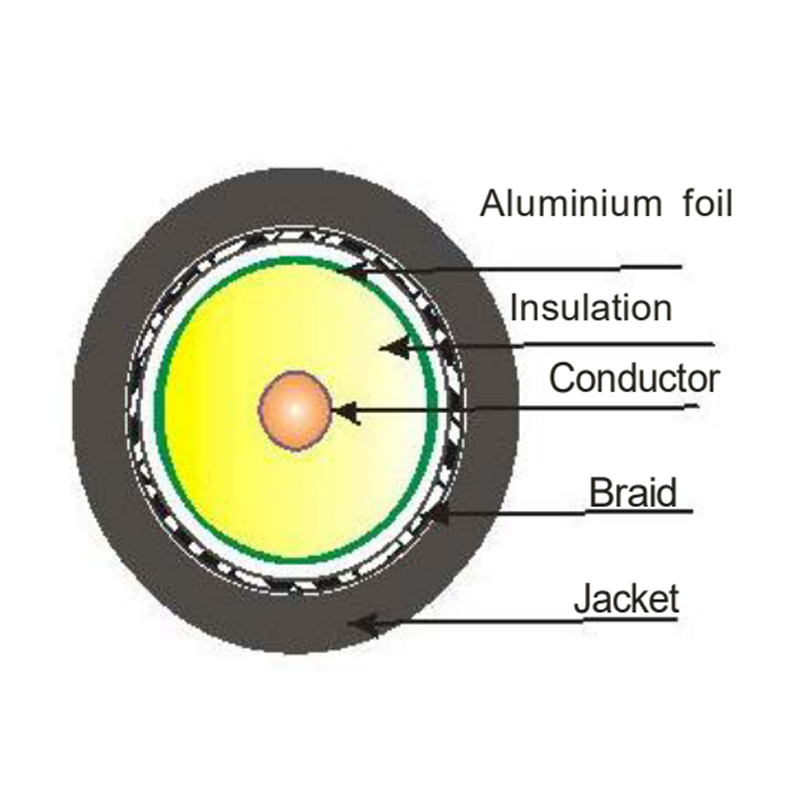

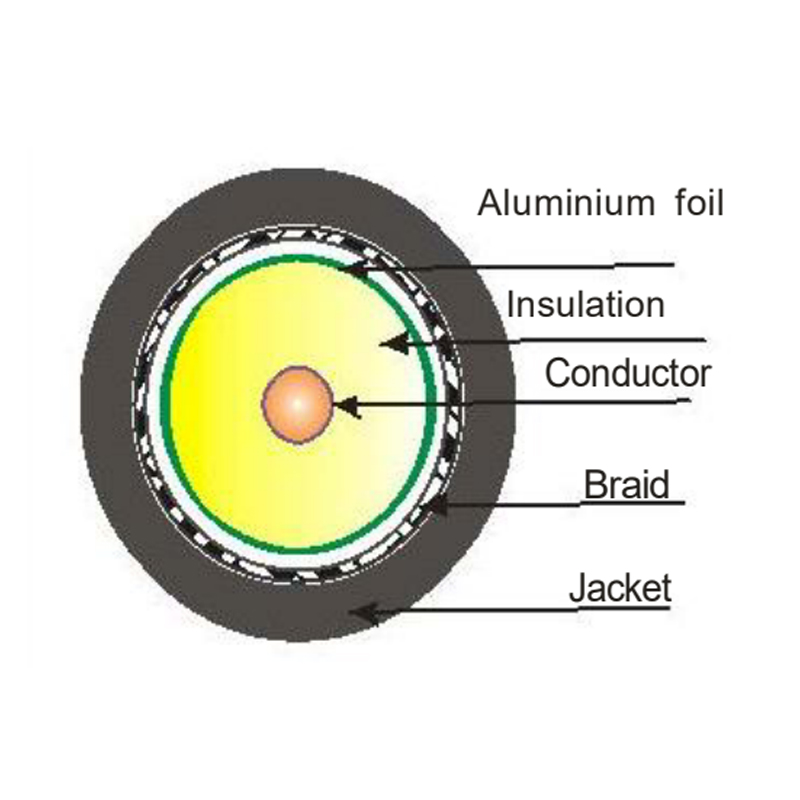

3.1 Conductor

Plain annealed stranded circular copper conductor in accordance

with IEC 60228 Class 2

3.2 Insulation

Extruded XLPE compound comply with EN 50288-7

Core identification(single):

Pair: White, Black

Triple: White, Black, Red

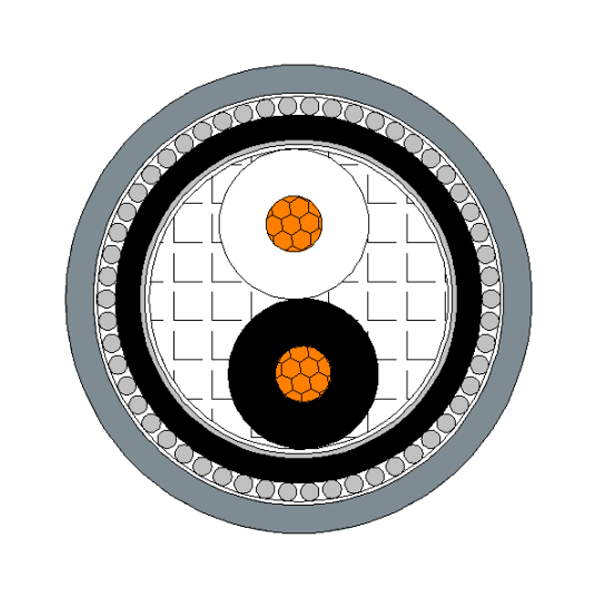

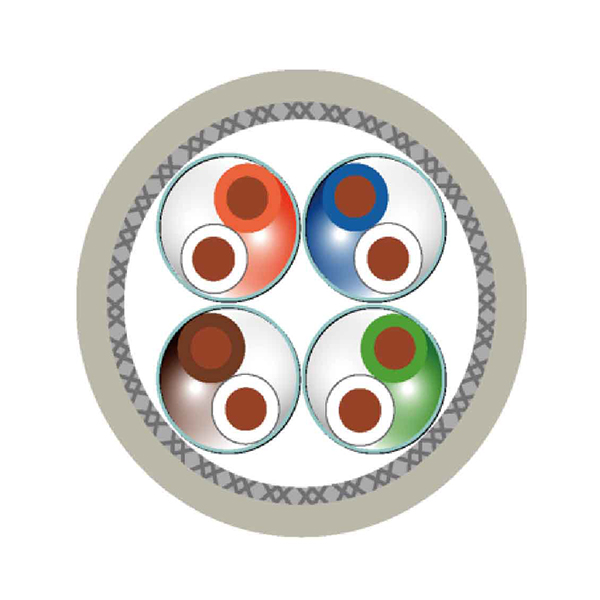

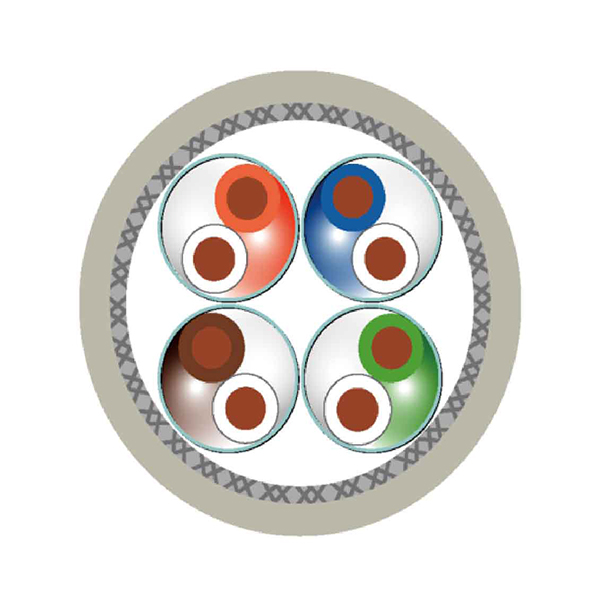

3.3 Twisted core

To form a pair/ triple, the insulated conductors twisted together

Lay length for pair / triple:

≤70mm for 1mm2; ≤100mm for 1.5mm2; ≤150mm for 2.5mm2;

3.4 Assembly and filler(optional)

The interstices between cores filled with non-hygroscopic

polypropylene rope to form substantially circular shape with a

suitable binder tape

3.5 Collective screen

Aluminum-polyester tape shield applied on assembly core, the

metallic side down in electrical contact with a drain wire (0.5mm2)

3.6 Inner sheath

Extruded LSZH compound comply with EN 50288-7

Color: Black

3.7 Metal amour

A layer of galvanize steel wires with suitable binder tape helically

applied on the inner sheath

3.8 Outer sheath

Extruded LSZH compound comply with EN 50288-7

Color: Grey (Non-intrinsically safe)

Light Blue (Intrinsically safe)

Orange (Telecom)

For example:

EAC YANGER® IEC 60332-3-22 CU/XLPE/OS/LSZH/SWA/LSZH 1Pair×1.5 SQMM 300/500V нг (А) – HF Project

Cable Code -52°C~+40°C 2020 ****M

Note: “****M” meter marking by inkjet with increased sequence with numbering

“нг (А) – HF” at least every 1 metre appear on the cable

| Rated voltage, U0/U, V | 300/500 |

| Rated, operating temperature range, ℃ | -52~+80 |

| Min. installation temperature without preheating, ℃ | -30 |

| Max. conductor temperature in service, ℃ | 90 |

| Max. permissible short-circuit temperature,5 sec, ℃ | 250 |

| Min. bending radius, D overall diameter of cable | 15D |

| Flame retardant | IEC 60332-3-22 |

| Halogen Gas Emission | IEC 60754-1, < 0.5% |

| Low Smoke Emission | IEC 61034-1/2 |

| UV resistant | UL 1581 |

| Oil resistant | IEC60811(IRM 902 – 4h at 70°C,variation ±40%) |

| Oxygen Index(Sheath) | ASTM D 2863 |

| Cold bend | IEC 60811-1-4, -52℃ |

| Cold impact | IEC 60811-1-4 & CSA C22.2 No.38-10, -52℃ |

| Chemical resistance | Accidental |