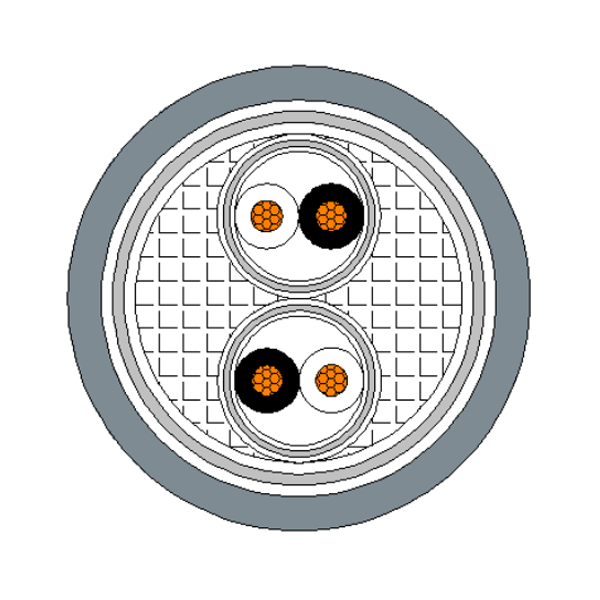

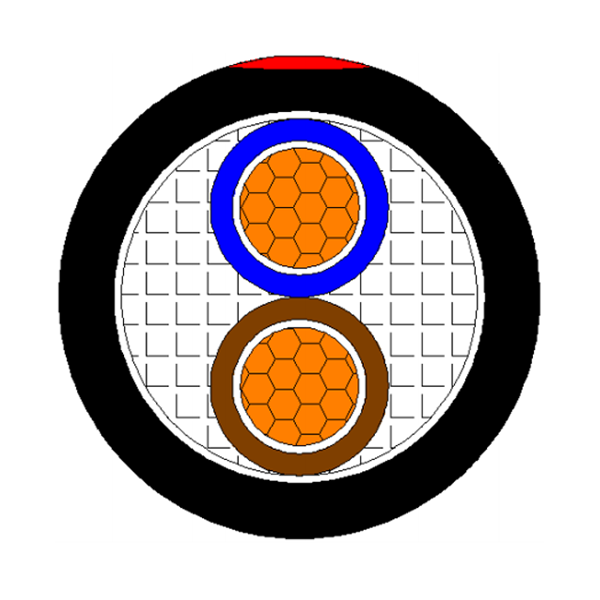

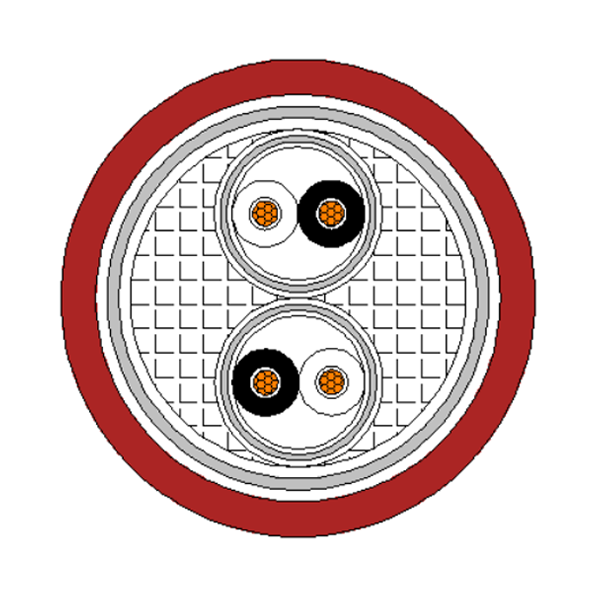

300/500V CU/XLPE/IS/OS/LSZH/SWA/LSZH Instrument Cable

For used in control systems for analogue or digital signal transmission, suitable for outdoor use at

temperature range from -52℃ to +80℃.

3.1 Conductor

Plain annealed stranded circular copper conductor in accordance

with IEC 60228 Class 2

3.2 Insulation

Extruded XLPE compound comply with EN 50288-7

Core identification*(Multi-):

Pair: White, Black

Triple: White, Black, Red

*each pair/triple is printed with number

Lay length for pair / triple:

≤70mm for 1mm2; ≤100mm for 1.5mm2; ≤150mm for 2.5mm2;

3.3 Individual screen

Aluminum-polyester tape shield with a binder tape applied on Each

pair/triple, the metallic side down in electrical contact with a drain

wire (0.5mm2)

3.4 Assembly and filler(optional)

The interstices between cores filled with non-hygroscopic

polypropylene rope to form substantially circular shape with a

suitable binder tape

3.5 Collective screen

Aluminum-polyester tape shield applied on assembly core, the

metallic side down in electrical contact with a drain wire (0.5mm2)

3.6 Inner sheath

Extruded LSZH compound comply with EN 50288-7

Color: Black

3.7 Metal amour

A layer of galvanize steel wires with suitable binder tape helically

applied on the inner sheath

3.8 Outer sheath

Extruded LSZH compound comply with EN 50288-7

Color: Grey (Non-intrinsically safe)

Light Blue (Intrinsically safe)

Orange (Telecom)

For example:

EAC YANGER® IEC 60332-3-22 CU/XLPE/IS/OS/LSZH/SWA/LSZH 2Pair×1 SQMM 300/500V нг (А) – HF Project

Cable Code -52°C~+40°C YEAR ****M

Note: “****M” meter marking by inkjet with increased sequence with numbering

“нг (А) – HF” at least every 1 metre appear on the cable

| Rated voltage, U0/U, V | 300/500 |

| Rated, operating temperature range, ℃ | -52~+80 |

| Min. installation temperature without preheating, ℃ | -30 |

| Max. conductor temperature in service, ℃ | 90 |

| Max. permissible short-circuit temperature,5 sec, ℃ | 250 |

| Min. bending radius, D overall diameter of cable | 15D |

| Flame retardant | IEC 60332-3-22 |

| Halogen Gas Emission | IEC 60754-1, < 0.5% |

| Low Smoke Emission | IEC 61034-1/2 |

| UV resistant | UL 1581 |

| Oil resistant | IEC60811(IRM 902 – 4h at 70°C,variation ±40%) |

| Oxygen Index(Sheath) | ASTM D 2863 |

| Cold bend | IEC 60811-1-4, -52℃ |

| Cold impact | IEC 60811-1-4 & CSA C22.2 No.38-10, -52℃ |

| Chemical resistance | Accidental |