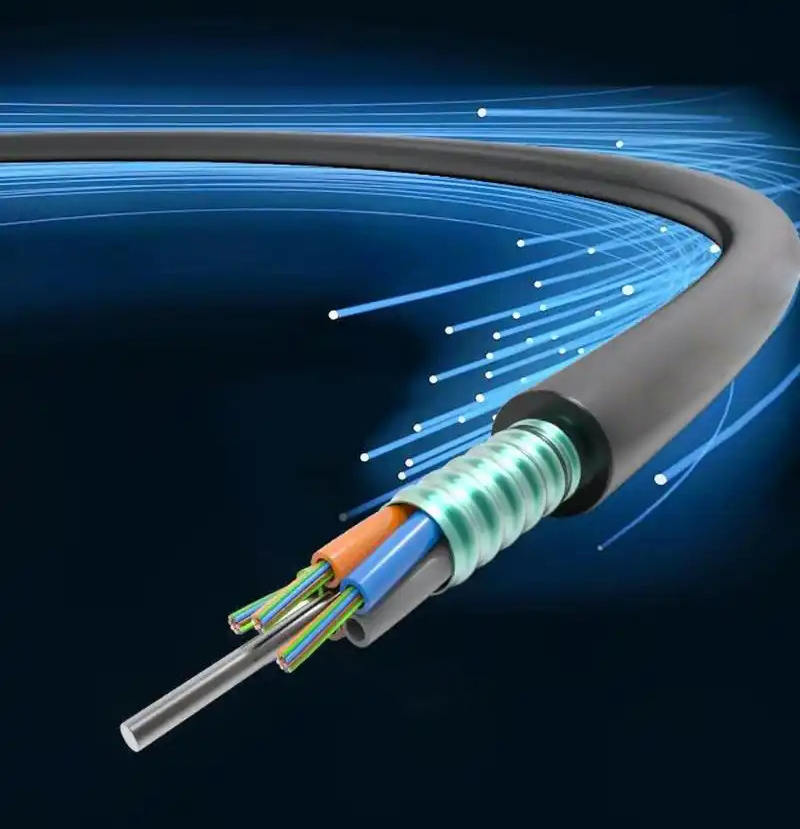

In the information age, with the rapid development of the Internet, the popularity of fiber optic communication is increasing. Fiber optic communication has become an integral part of our daily lives and work, such as online shopping, online education, and internet-based office work, enhancing efficiency and bringing great convenience. Fiber optic communication, as the name suggests, is a communication method that uses optical fibers as the transmission medium. However, optical fibers are extremely thin and brittle, making them prone to breakage. To meet optical, mechanical, or environmental performance specifications, optical fibers are protected by an outer layer and are manufactured into optical cables through specific processes.

As communication cables based on optical technology, optical cables are widely used in various scenarios and can meet the demands of modern high-speed internet, especially for long-distance communication. Compared to traditional copper cables, optical cables offer a wider transmission bandwidth, higher resistance to interference, and lower signal attenuation, resulting in higher transmission speeds and lower signal loss. In addition, fiber optic communication has the advantages of minimal leakage and strong confidentiality, making it suitable for special environments or military applications. Therefore, the superiority of fiber optic communication is extremely high, and it is an inevitable direction for the development of communication.

However, ordinary optical cables are difficult to apply in the marine and offshore industry. The marine environment imposes special requirements on the fiber optic communication systems equipped on ships in terms of temperature, salt fog, vibration, safety, and other aspects. These requirements include low toxicity, halogen-free and low-smoke, flame retardancy, resistance to electromagnetic interference, and resistance to impact and vibration. Shipboard optical cables are a series of fiber optic cables specifically designed for the marine environment and represent a major branch of special optical cables. With the rapid development of shipborne monitoring, control, and communication systems, shipboard optical cables have replaced the use of cables in some scenarios. Currently, optical cables on ships are mainly used for video surveillance, network access, navigation, and entertainment, playing a crucial role in modern ship communication systems.

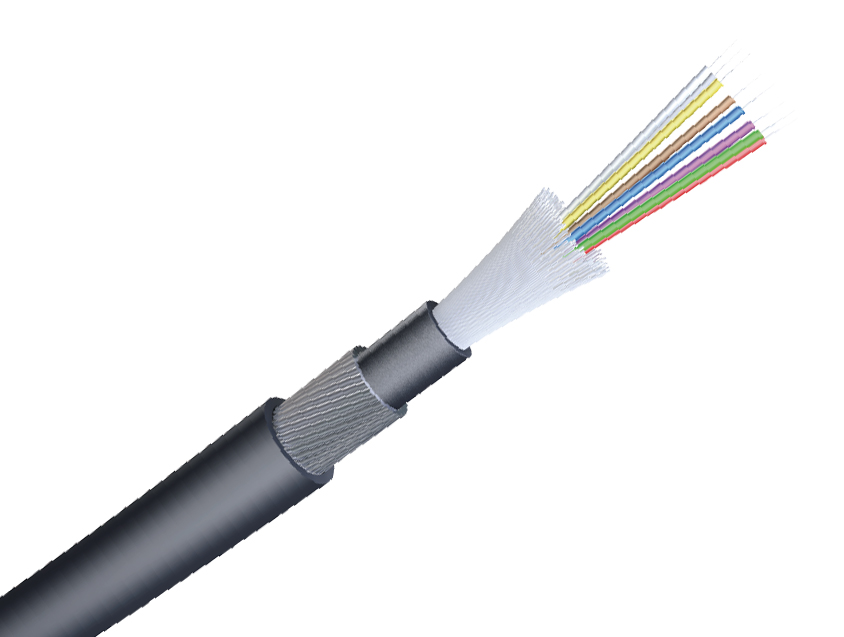

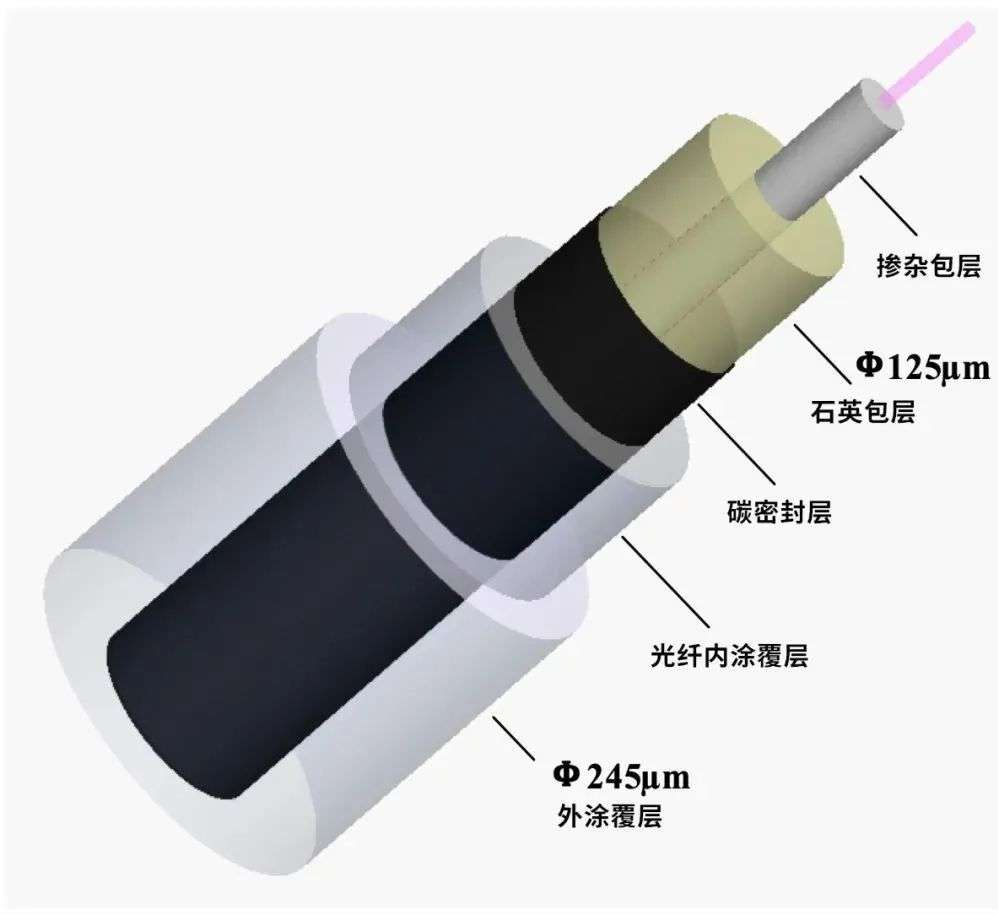

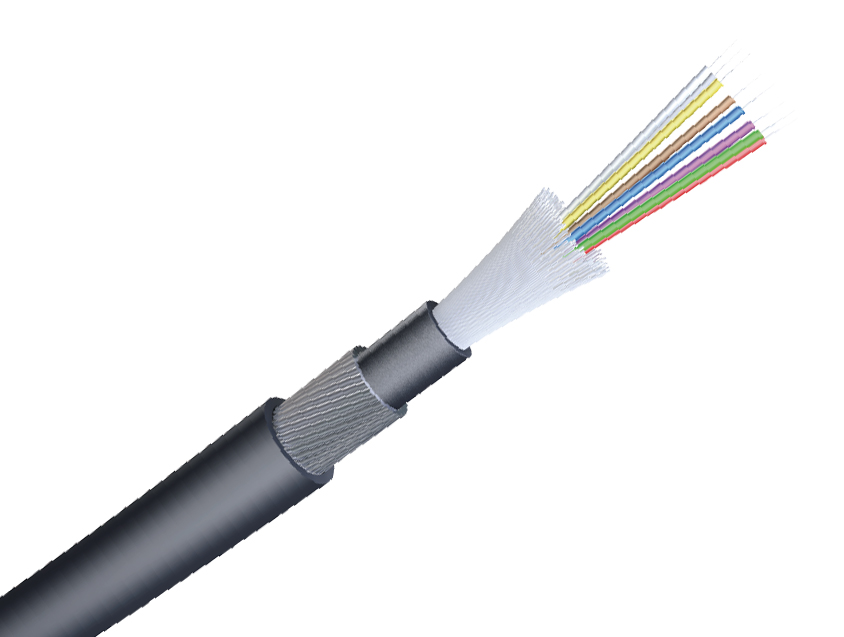

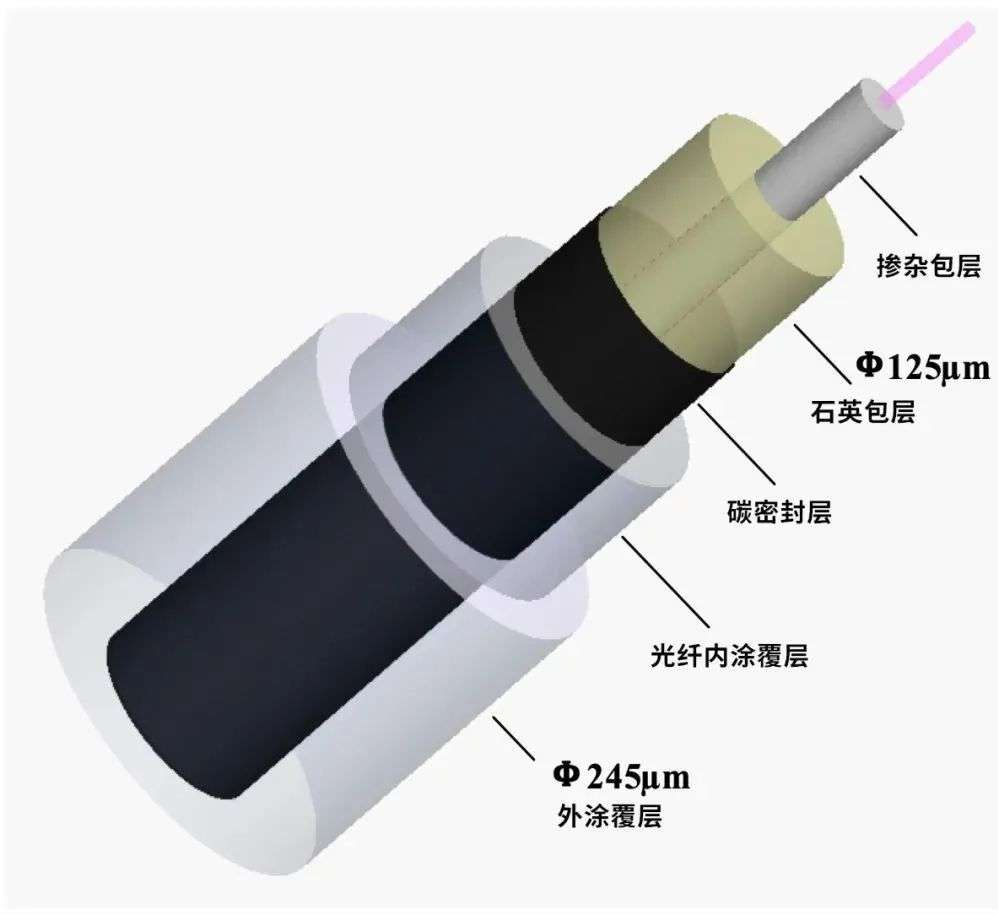

To ensure the stability of the communication network for marine operations, shipboard optical cables must meet the aforementioned special requirements for marine use, as well as various standards and specifications. Therefore, the structure of shipboard optical cables is more complex, and the requirements for craftsmanship and technology are higher, which also gives them superior transmission, mechanical, and environmental performance. The general composition of shipboard optical cables includes: optical fibers, tubes, reinforcement members, water-blocking layers, fire-resistant layers, armor, and jackets. Among these, optical fibers typically consist of three parts: the core, cladding, and coating layer, forming a concentric circle structure. The core is located at the center, and the common material for the fiber core is high-purity silica. The cladding is located around the core, also made of high-purity silica. The cladding provides a reflective surface and optical isolation for light transmission and offers a certain degree of mechanical protection. The coating layer is the outermost layer of the optical fiber, composed of acrylate, silicone rubber, and nylon, protecting the fiber from moisture and mechanical abrasion.

For different application scenarios, shipboard optical cables have various structures, too numerous to mention; and the materials used for each component of the cable’s structure are not the same.

According to different classification criteria, shipboard optical cables can be divided into various types.

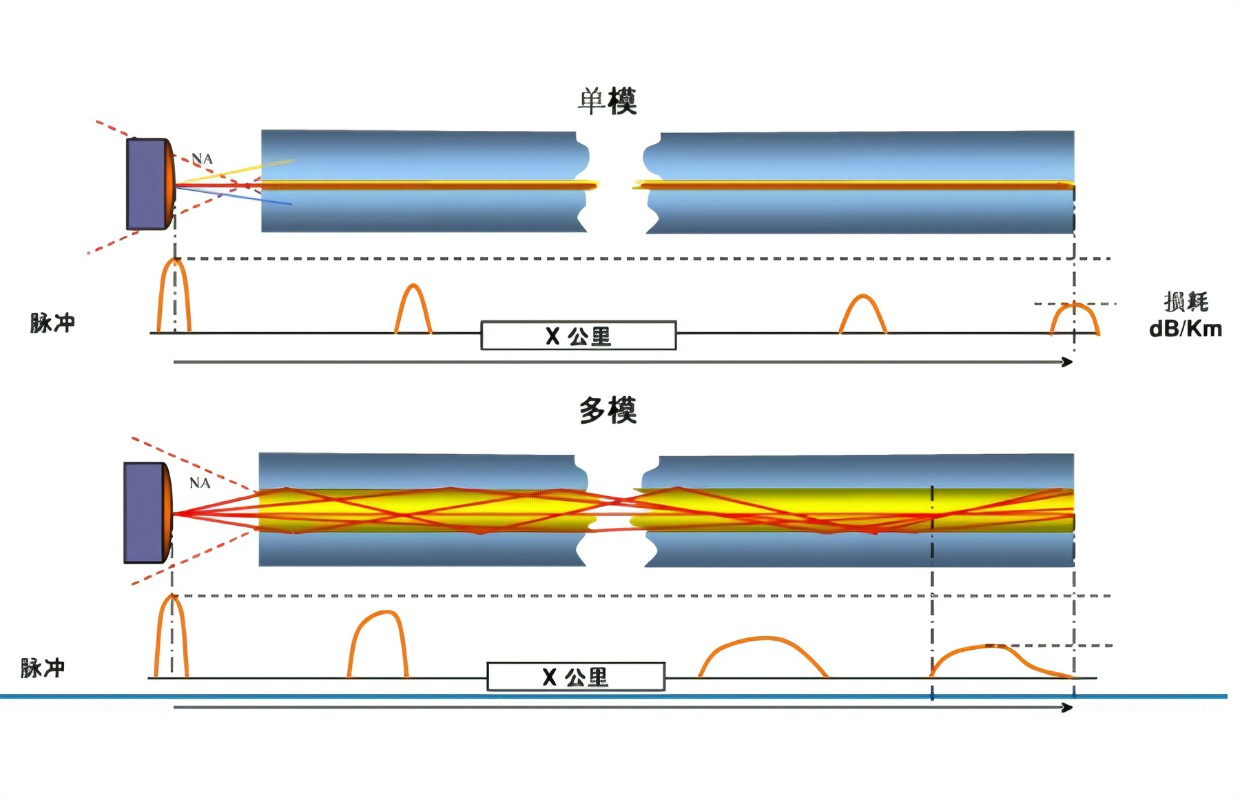

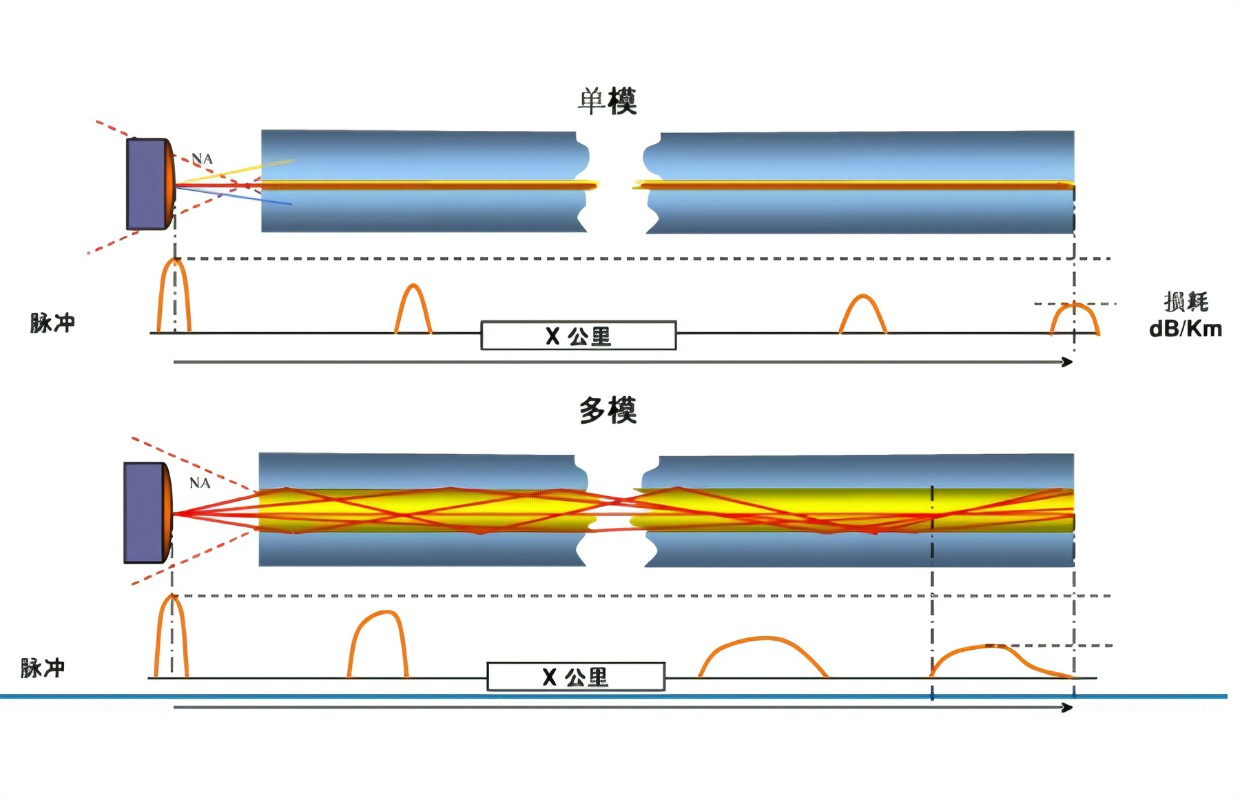

Based on the type of optical fiber within the cable, they can be categorized into single-mode and multi-mode optical cables. Single-mode optical cables use single-mode fibers (Single-Mode, SM), while multi-mode optical cables contain multi-mode fibers (Multi-Mode, MM).

Single-mode fibers allow only one mode (the fundamental mode) of light to propagate through the fiber. Their core diameter typically ranges from 8 to 10 μm, which is much smaller than that of multi-mode fibers. The cladding diameter of single-mode fibers is generally 125 μm, and the overall fiber diameter is about 250 μm. Due to the very small core diameter, only light waves at specific angles can enter and remain within the core for propagation, thereby reducing modal dispersion and enabling longer-distance transmission. In summary, single-mode fibers have the characteristics of long transmission distance, high bandwidth, and low loss. Therefore, they are mainly used in long-distance communication, broadcasting and television, military communication, and other fields.

Multi-mode fibers permit multiple modes of light to propagate through the fiber. The core diameter of multi-mode fibers usually ranges from 50 to 62.5 μm, and both the cladding and overall fiber diameters are similar to those of single-mode fibers. However, because of the larger core diameter, light waves entering at different angles can propagate through the fiber along different paths, forming multiple modes. These modes can cause modal dispersion during propagation, potentially leading to signal distortion. Compared to single-mode fibers, multi-mode fibers are less expensive and easier to install. Consequently, multi-mode optical cables are often used in local area networks, data centers, industrial control, and other scenarios with relatively lower requirements.

Currently, shipboard optical cables predominantly use single-mode fibers for medium to long-distance transmission, while the internal local area networks of ships more frequently employ multi-mode fibers that are easier to install and more cost-effective.

In addition, optical cables can also be classified based on the number of fiber cores inside, into single-core and multi-core optical cables; or according to different structural methods, into flat-structured optical cables, stranded optical cables (used for vertical cabling), skeleton optical cables, armored optical cables (used for direct burial cabling), and so on.

Shipboard optical cables need to comply with many standards and specifications. For example, the color coding of optical fibers must follow the EIA/TIA-598 standard, which is a globally recognized fiber optic cabling standard. The color differentiation helps us quickly identify the type of fiber and maintain fiber optic cabling.

When a ship is sailing on the sea, in the event of a fire, it is difficult for the crew to evacuate. The cables used on ships are flammable, and the smoke produced during combustion can be extremely harmful to human health. To reduce the harm and loss caused by fires, shipboard optical cables generally use low-smoke zero-halogen (LSZH SHF1) jacket materials that meet the IEC 60332 flame retardant requirements, as well as the IEC 60754-1/2 and IEC 61034-1/2 low-smoke zero-halogen requirements. In some special scenarios, a mica tape fire-resistant layer is added to the cable to meet the IEC 60331 fire resistance requirements. This ensures that the communication system can operate normally for a certain period after a fire starts, thereby safeguarding lives and property and minimizing losses.

Shipboard optical cables must adapt to the marine environment while also ensuring reliability and safety when used on ships. In terms of temperature, shipboard optical cables are required to operate normally in extreme temperature conditions, with a broader temperature range typically from -40°C to 70°C. Regarding materials, shipboard optical cables need to use corrosion-resistant and waterproof materials. In terms of standards, shipboard optical cables must pass strict certifications from the International Maritime Organization (IMO) and classification societies (such as DNV, ABS, CCS, etc.).

Post time:

Jan-13-2025