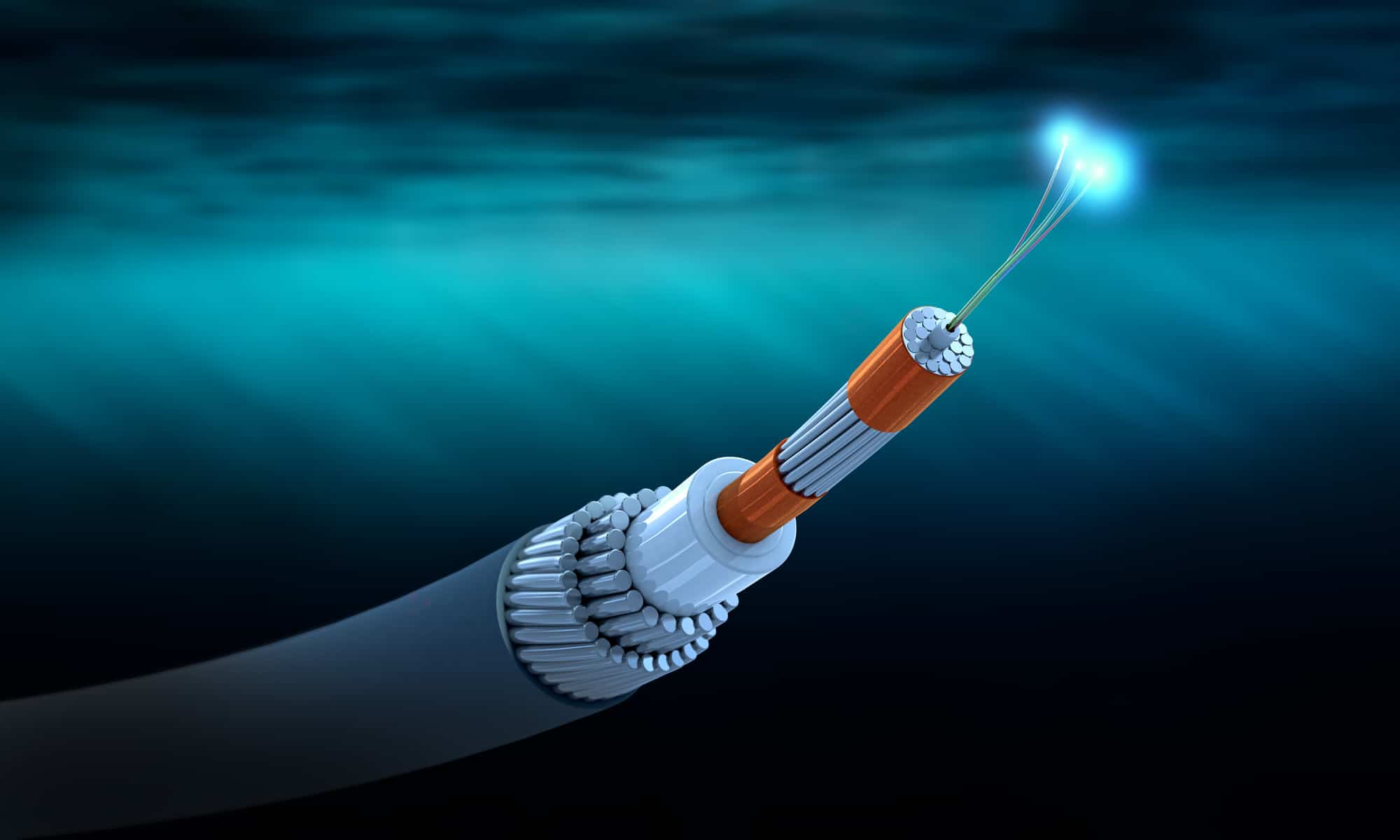

What specifications and requirements do the structural design of marine network cables need to meet? Generally speaking, marine network cables, as a medium for network data transmission, must first comply with the international standard ISO/IEC 11801, and secondly meet the specifications of multi-core symmetrical cables for digital communication IEC 61156-1 and IEC 61156-5. As a type of cable applied to marine engineering installations, marine network cables also need to meet the standards of IEC 60092-350 and IEC 60092-360 for cables used in control and instrumentation circuits for ships and offshore installations. In addition, according to the different application scenarios of marine network cables, there are flame retardant standards IEC 60332-1-2-3-22, fire resistance standards IEC 60331-23, combustion acidic gas content standards IEC 60754, combustion smoke density standards IEC 61034, mud resistance standards NEK TS 606, as well as RoHS-2 2011/65/EU regulations restricting the use of harmful substances in electrical and electronic equipment (EEE) and UV resistance standards UL1581.

ISO/IEC 11801

ISO/IEC 11801 is written and revised by the ISO/IEC JTC1 SC25 Committee of the International Organization for Standardization, and its full name is Information Technology – User Infrastructure Structured Cabling. It describes how to design a universal structured cabling for various network applications, including analog and ISDN technology, multiple network transmission protocols, and applications such as control systems, industrial automation, and HDBASE-T. In addition, the performance level and transmission distance of twisted pair and optical cable wiring are clearly stated in this standard.

In the Chinese standard classification, it involves multiple fields such as system equipment interfaces, cables and their accessories, communication engineering, electrical equipment installation engineering, communication network technology system, data communication, telecommunications equipment installation engineering, electronic equipment wires, cables, basic standards and general methods. The importance of this standard lies in its provision of a universal structured cabling standard, allowing various different network applications to share the same cabling, thereby reducing the complexity and cost of cabling. At the same time, the standard also specifies performance levels and transmission distance indicators for wiring to ensure that it can meet various network application requirements.

IEC 61156

IEC 61156 is a set of specifications for multi-core symmetrical cables for digital communication, which includes multiple parts, each of which provides detailed regulations for specific types of cables and specific working environment conditions.

Among them, IEC 61156-1 is a general specification for multi-core symmetrical cables for digital communication, which specifies the overall requirements, test methods, and marking requirements of cables. This specification applies to multi-core symmetrical cables used in digital communication, including twisted pair, star twisted pair, four core cables, etc.

The IEC 61156-5 specification specifies in detail the horizontal floor wiring and profile specifications for symmetrical twisted pair/four wire cables with transmission characteristics up to 1000 MHz This specification requires that cables must have a suitable structure that can meet usage requirements, and the materials of the cables must also comply with relevant standard requirements. In addition, it also specifies the transmission characteristics of the cable, including attenuation, crosstalk, return loss and other indicators, to ensure that the cable can meet the requirements of digital communication.

IEC 60092

IEC 60092 is a standard for cables used in control and instrumentation circuits for ships and offshore installations, which mainly specifies the rated voltage, insulation materials, structural requirements, and test methods of cables.

Specifically, the IEC 60092 standard includes multiple parts, such as Part 350, which cover the electrical, mechanical, and environmental performance requirements of cables to ensure that they can function properly in various environments on board ships and offshore installations. This standard specifies in detail the structural requirements for power, control, and instrumentation cables for ships and nearshore use, including conductor materials, insulation layer materials, sheath materials, etc. At the same time, it also puts forward requirements for the mechanical performance and environmental adaptability of cables, such as vibration resistance, impact resistance, corrosion resistance, etc. In addition, IEC 60092-350 specifies various testing methods, such as insulation resistance test, voltage withstand test, mechanical performance test, etc. These tests aim to ensure that the various performance indicators of the cable meet the standard requirements, in order to ensure its stability and reliability in practical use.

And IEC 60092-360 specifies the insulation materials for cables, especially the requirements for insulation and sheath materials for shipborne and offshore complete sets, power, control, instrumentation, and long-distance communication cables, including single-layer insulation, double-layer or multi-layer insulation, as well as a combination of one or more layers of inorganic tape and single or multi-layer insulation materials. This standard involves the fire resistance, waterproof performance, corrosion resistance, etc. of cables.

IEC 60332-1-2/3-22

IEC60332-1-2 is a test method standard for cables and optical cables issued by the International Electrotechnical Commission (IEC), mainly used to evaluate the flame-retardant performance of cables and optical cables under fire conditions. This standard specifies the test method for vertical flame propagation of individual wires and cables to evaluate their flame-retardant ability under fire conditions. Specifically, IEC60332-1-2 specifies the following testing methods and requirements:

Premixed flame test method: Place the wire or cable at a selected height, conduct a combustion test using a specific gas flame, and observe its flame spread. This test method aims to simulate the combustion behavior of cables under fire conditions.

Flame retardant rating evaluation: The flame-retardant rating of wires or cables is evaluated based on parameters such as flame propagation time and combustion length during the testing process. Usually, a qualified flame-retardant rating requires that the flame spread time does not exceed a certain standard, and the combustion length cannot exceed a specific value.

For the flame-retardant performance testing of bundled cables, the IEC 60332-3-22 standard should be used for evaluation.

IEC60331-23

IEC 60331-23 is a test standard issued by the International Electrotechnical Commission (IEC) for cables under fire conditions, aimed at evaluating the fire resistance performance and safety of cables under fire conditions. This standard specifies the testing methods and acceptance criteria for cables under fire conditions. Specifically, the IEC 60331-23 standard includes the following content and requirements:

Flame test method specifies the flame test method for cables under ignition conditions, including parameters such as flame application method, flame temperature, combustion time, etc.

Integrity requirements for cables: It is stipulated that cables should maintain their integrity during the flame test process, and there should be no obvious combustion, melting, short circuit or other phenomena.

Voltage retention requirement: During the flame test, the cable should maintain its voltage unchanged and there should be no voltage drop or open circuit.

IEC 60754

IEC 60754 is an international standard issued by the International Electrotechnical Commission (IEC) for determining the content of acidic gases released during the combustion process of polymer materials. The purpose of this standard is to evaluate the flame retardancy and environmental friendliness of materials to ensure that they do not cause significant harm to personnel and the environment during use. Specifically, the IEC 60754-1 method specifies that when the combustion furnace is preheated to 800 ℃, a 1.0g sample is pushed into the furnace, and HCL is dissolved in water using the airflow discharge rate, and then the halogen acid content of the aqueous solution is measured. If the release of halogenated acid (HCL) is greater than 5mg/g but less than 15mg/g, it can be called low halogen cable (LSF).

It is worth noting that the IEC60754-1 method cannot be used to determine whether materials with HCL content less than 5 mg/g are halogen-free. To determine whether it is completely halogen-free, the IEC60754-2 method can be used. If the amount of halogen acid (HCL) released during the combustion of cable materials is less than 5mg/g, it can be called halogen-free cable (LSOH/LSZH).

IEC 61034

IEC 61034 is a standard issued by the International Electrotechnical Commission (IEC) for determining the smoke density of cables during combustion under specific conditions. The smoke density test method specified in the IEC 61034 standard is to place the cable or cable accessories in a closed test box, apply flames to ignite them, and record the smoke generation. During the testing process, by measuring the time it takes for smoke to fill the test chamber and the concentration of smoke, the release of smoke from cables or cable accessories during a fire can be evaluated.

According to the IEC 61034 standard, qualified cables or cable accessories should meet the low smoke standard when caught on fire. These standard measures smoke density based on light transmittance. If the light transmittance can reach 60%, the cable material will meet the low smoke standard. The higher the light transmittance, the less smoke the material releases during combustion. At the same time, it is also required that cables and their accessories maintain their integrity in the event of fire, and there should be no obvious combustion, melting, short circuit or other phenomena to reduce the impact on the environment and personnel.

NEK TS 606

NEK TS 606 is recognized as the most competitive technical standard for marine engineering cables in the industry, compiled and published by the Norwegian Electricity Council (NEK). In marine environments, cables may come into contact with various types of oil stains, such as lubricating oil, hydraulic oil, etc. NEK TS 606′s oil resistance requirements for cables mainly refer to their ability to maintain stable performance in harsh oil pollution environments. The specific testing requirements for Class C mud resistance are: soaking in IRM 902 mineral oil at 100 ℃ for 7 days, soaking in IRM 903 mineral oil at 100 ℃ for 7 days, soaking in calcium bromide solution at 70 ℃ for 56 days, and soaking in EDC 95-11 drilling fluid at 70 ℃ for 56 days. The mechanical and physical properties of the cable sheath material meet the requirements and are suitable for installation and operation in an environment in contact with mud.

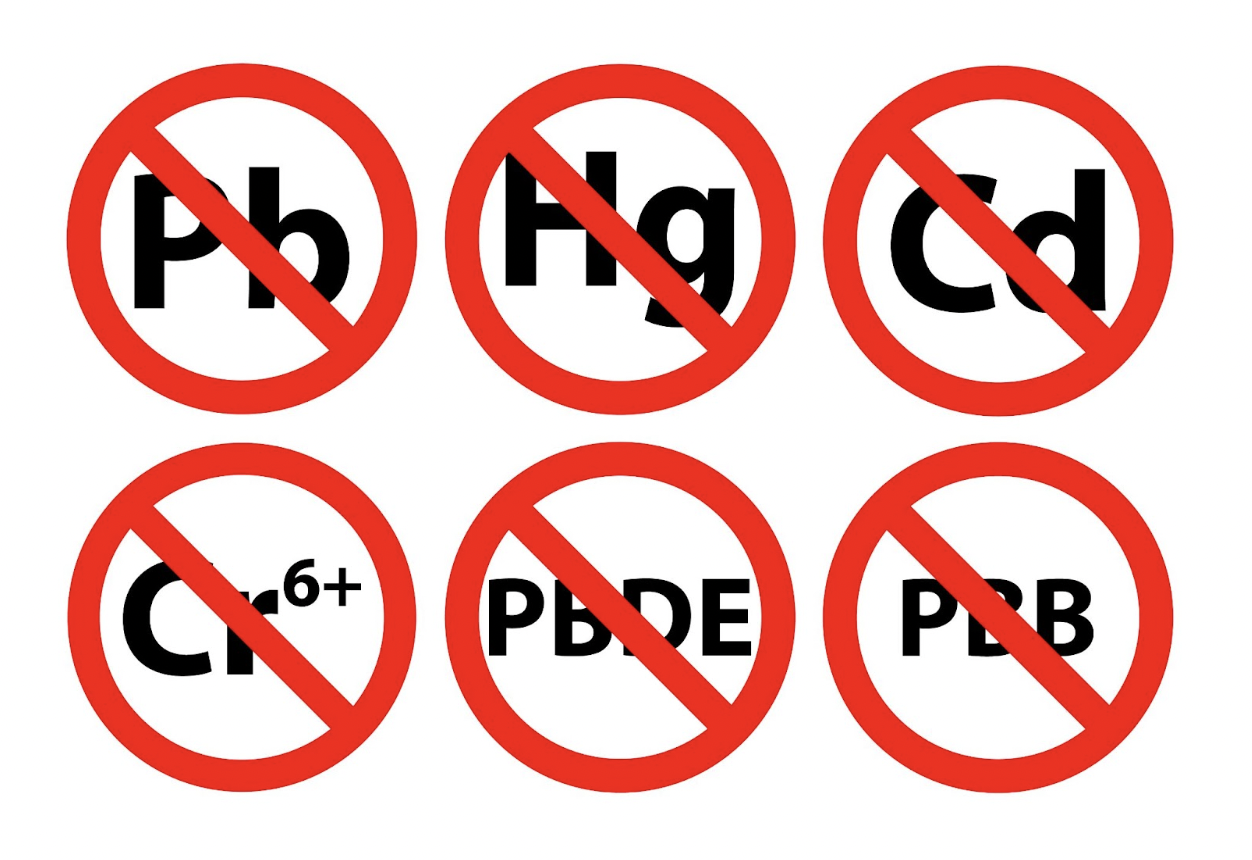

RoHS-2 2011/65/EU

The purpose of RoHS-2 2011/65/EU regulation is to protect human health and the environment, as well as the environmentally friendly recycling and disposal of waste EEE. It stipulates restrictions on the use of harmful substances in electrical and electronic equipment (EEE), such as mercury, lead, cadmium, polybrominated biphenyls, dibutyl phthalate, di isobutyl phthalate, hexavalent chromium, polybrominated biphenyl ethers, etc. For electronic and electrical equipment manufacturers, RoHS-2 2011/65/EU has put forward multiple requirements. In order to prove CE compliance with RoHS-2 2011/65/EU, manufacturers must conduct a conformity assessment, issue a conformity declaration, and affix the CE mark on their products.

UL1581

UL 1581 is a standard used to evaluate the performance of wires and cables under ultraviolet (UV) radiation. It is mainly used to evaluate whether the structure and performance of wires and cables have changed after prolonged exposure to ultraviolet radiation when used outdoors.

The UL 1581 standard specifies the following testing methods and requirements:

1. UV irradiation test: Place the wires and cables under a UV lamp for irradiation for at least 200 hours. During the experiment, it is necessary to record the color changes, softening, cracking, and other changes of the wires and cables.

2. Electrical performance testing: After the UV irradiation test, the electrical performance of the wires and cables is tested, including the measurement of parameters such as conductor resistance and insulation resistance.

3. Appearance inspection: Conduct an appearance inspection on the wires and cables after UV irradiation, including observing color changes, whether there are bubbles, cracks, and other phenomena.

Post time: Dec-06-2023