OEM Customized Flexible Sub-Marine Rubber Cable H05rn-F 4*16

So as to provide you with ease and enlarge our business, we even have inspectors in QC Crew and guarantee you our best company and solution for OEM Customized Flexible Sub-Marine Rubber Cable H05rn-F 4*16, If you are intrigued in almost any of our items or would like to discuss a custom buy, you should really feel no cost to get hold of us.

So as to provide you with ease and enlarge our business, we even have inspectors in QC Crew and guarantee you our best company and solution for China Electric Wire and Wire Cable, Many items fully conform to the most rigorous of international guidelines and with our first-rate delivery service you will have them delivered at any time and in any place. And because Kayo deals in the entire spectrum of protective equipment, our customers don’t ought to waste time shopping around.

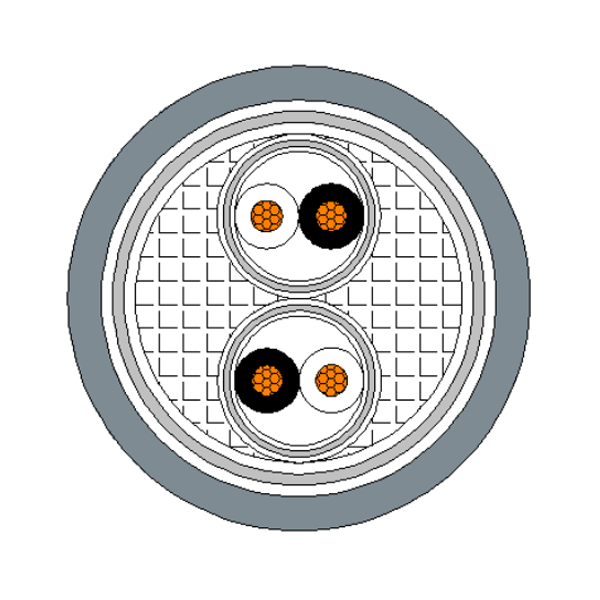

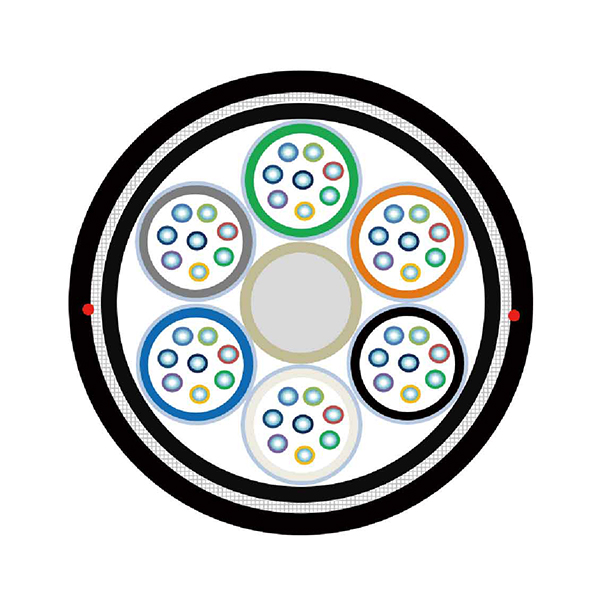

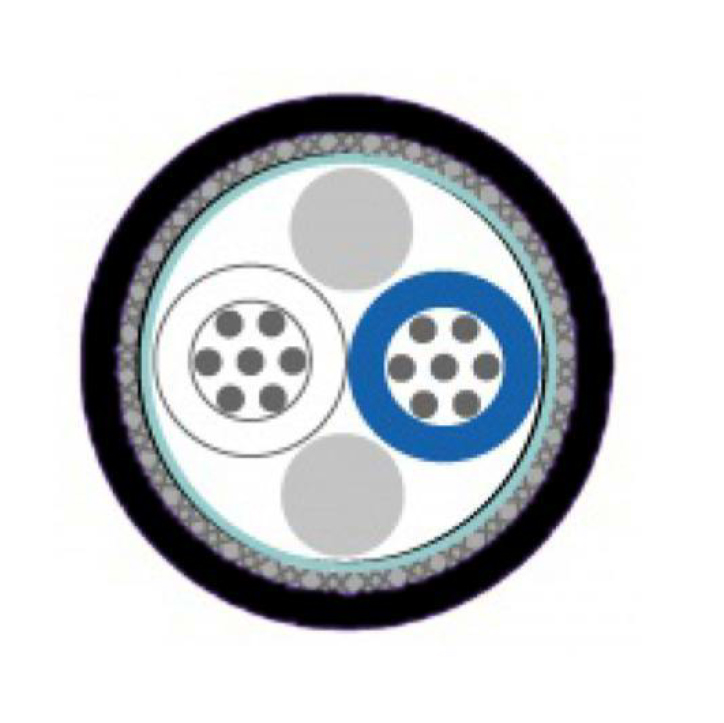

For used in control systems for analogue or digital signal transmission, suitable for outdoor use at

temperature range from -52℃ to +80℃.

So as to provide you with ease and enlarge our business, we even have inspectors in QC Crew and guarantee you our best company and solution for OEM Customized Flexible Sub-Marine Rubber Cable H05rn-F 4*16, If you are intrigued in almost any of our items or would like to discuss a custom buy, you should really feel no cost to get hold of us.

OEM Customized China Electric Wire and Wire Cable, Many items fully conform to the most rigorous of international guidelines and with our first-rate delivery service you will have them delivered at any time and in any place. And because Kayo deals in the entire spectrum of protective equipment, our customers don’t ought to waste time shopping around.

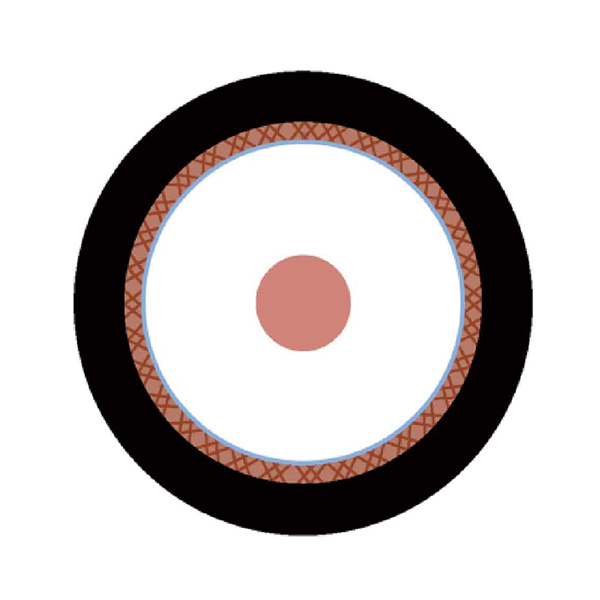

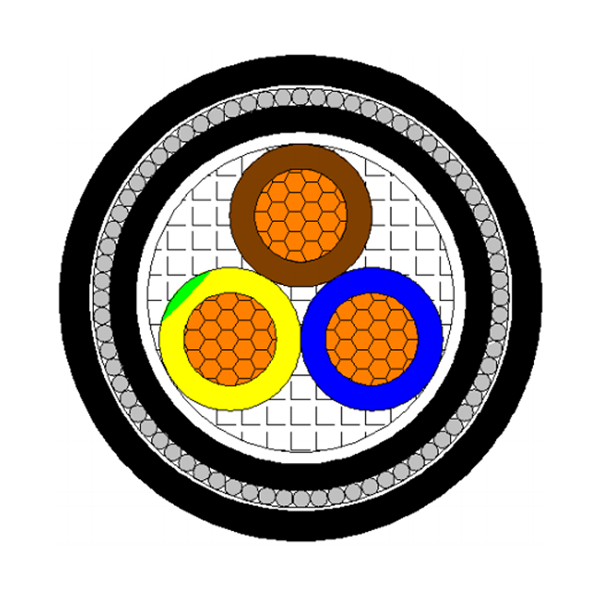

3.1 Conductor

Plain annealed stranded circular copper conductor in accordance

with IEC 60228 Class 2

3.2 Insulation

Extruded XLPE compound comply with EN 50288-7

Core identification*(Multi-):

Pair: White, Black

Triple: White, Black, Red

*each pair/triple is printed with number

Lay length for pair / triple:

≤70mm for 1mm2; ≤100mm for 1.5mm2; ≤150mm for 2.5mm2;

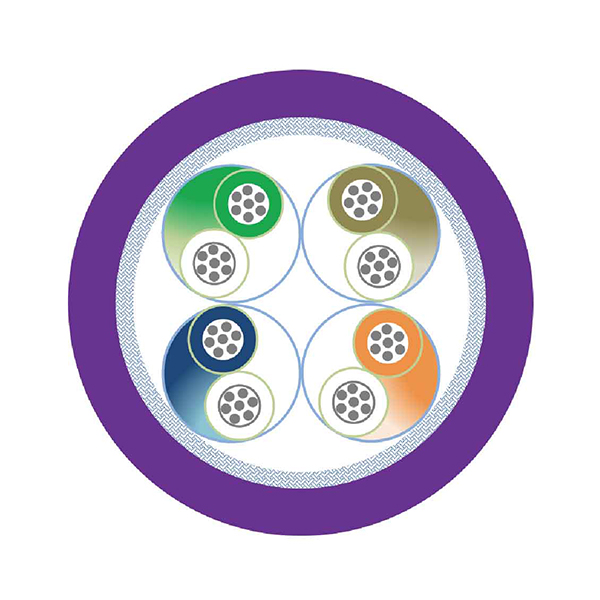

3.3 Individual screen

Aluminum-polyester tape shield with a binder tape applied on Each

pair/triple, the metallic side down in electrical contact with a drain

wire (0.5mm2)

3.4 Assembly and filler(optional)

The interstices between cores filled with non-hygroscopic

polypropylene rope to form substantially circular shape with a

suitable binder tape

3.5 Collective screen

Aluminum-polyester tape shield applied on assembly core, the

metallic side down in electrical contact with a drain wire (0.5mm2)

3.6 Binder Tape

Non-hygroscopic tape wrapped around the collective screen

3.7 Outer sheath

Extruded LSZH compound comply with EN 50288-7

Color: Grey (Non-intrinsically safe)

Light Blue (Intrinsically safe)

Orange (Telecom)

For example:

EAC YANGER® IEC 60332-3-22 CU/XLPE/IS/OS/LSZH 2Pair×1 SQMM 300/500V -52°C~+40°C YEAR ****M

Note: “****M” meter marking by inkjet with increased sequence with numbering

| Rated voltage, U0/U, V | 300/500 |

| Rated, operating temperature range, ℃ | -52~+80 |

| Min. installation temperature without preheating, ℃ | -30 |

| Max. conductor temperature in service, ℃ | 90 |

| Max. permissible short-circuit temperature,5 sec, ℃ | 250 |

| Min. bending radius, D overall diameter of cable | 15D |

| Flame retardant | IEC 60332-3-22 |

| Halogen Gas Emission | IEC 60754-1, < 0.5% |

| Low Smoke Emission | IEC 61034-1/2 |

| UV resistant | UL 1581 |

| Oil resistant | IEC60811(IRM 902 – 4h at 70°C,variation ±40%) |

| Oxygen Index(Sheath) | ASTM D 2863 |

| Cold bend | IEC 60811-1-4, -52℃ |

| Cold impact | IEC 60811-1-4 & CSA C22.2 No.38-10, -52℃ |

| Chemical resistance | Accidental |