China Manufacturer for Marine Engine Push Pull Control Cable

Our commission should be to provide our customers and consumers with ideal top quality and aggressive portable digital products for China Manufacturer for Marine Engine Push Pull Control Cable, We warmly welcome consumers, company associations and buddies from all over the planet to speak to us and find cooperation for mutual advantages.

Our commission should be to provide our customers and consumers with ideal top quality and aggressive portable digital products for China Electronic Wire Harness and High Quality Custom Cable Assembly, In order to make more people know our goods and to enlarge our market, now we have devoted a lot of attention to technical innovations and improvement, as well as replacement of equipment. Last but not the least, we also pay more attention to training our managerial personnel, technicians and workers in planned way.

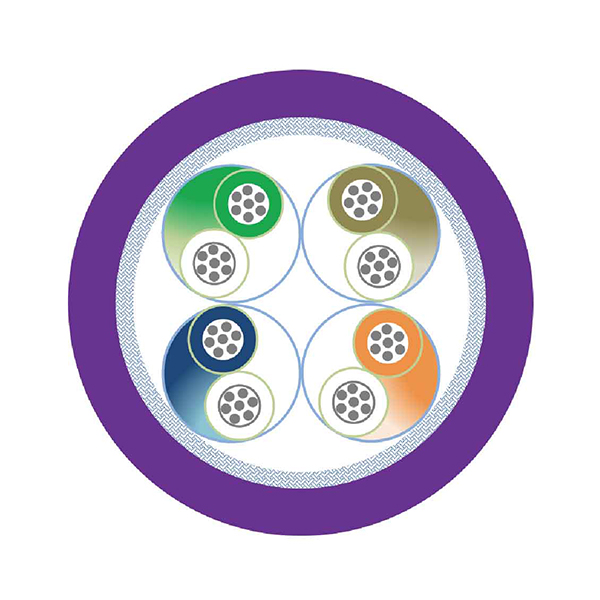

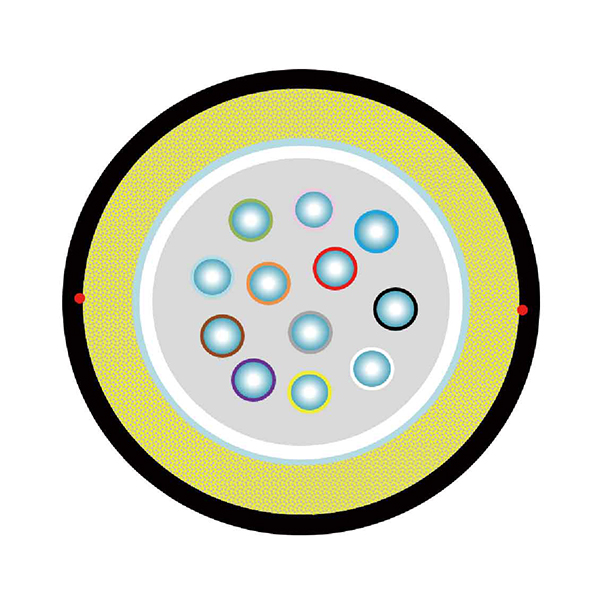

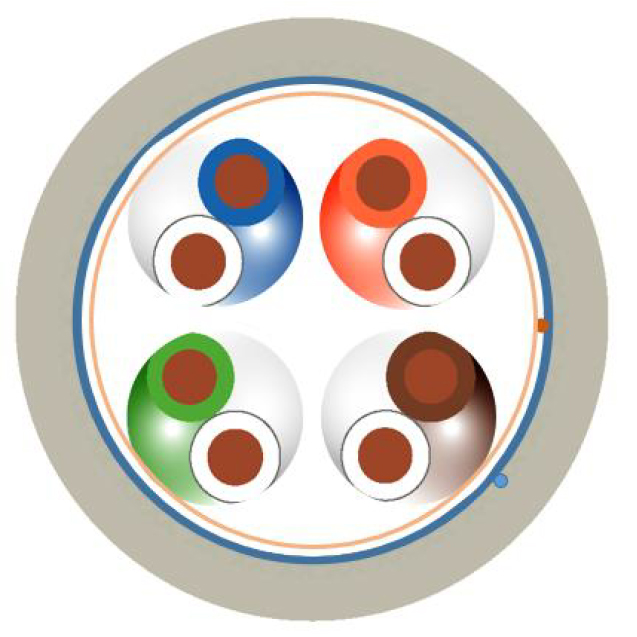

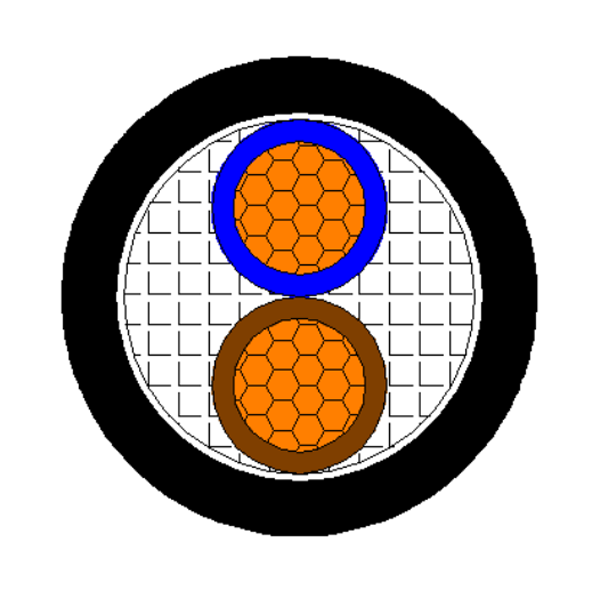

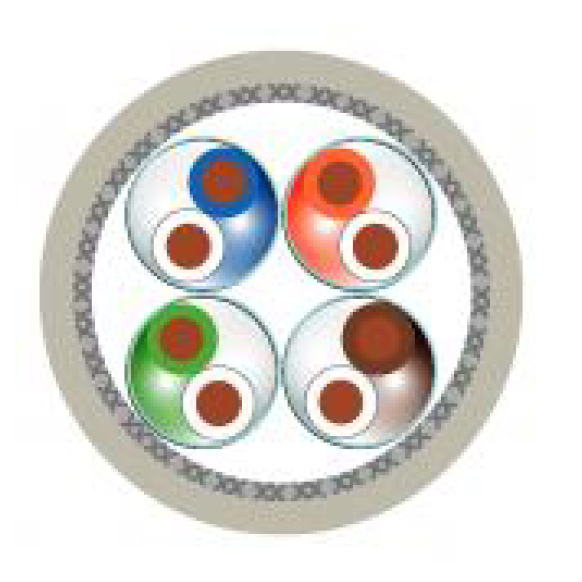

| Conductor: | Stranded tinned Copper AWG 22/7 (0.35 mm²), 1 Pair, 2 Pairs, 4 Pairs |

| Conductor Structure: | 7/0.25 ± 0.01 mm |

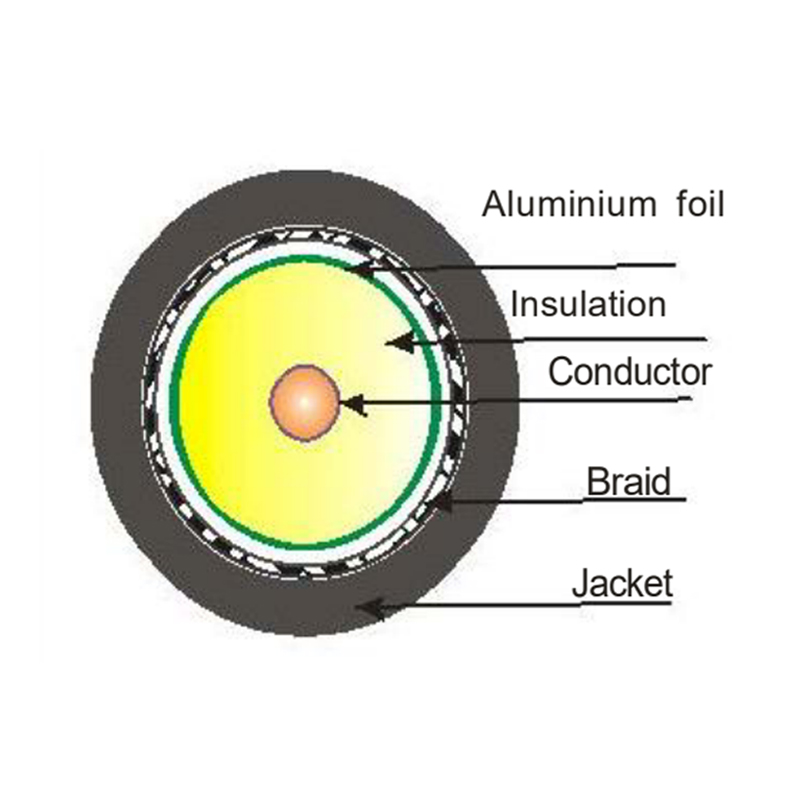

| Insulation: | Foam Polyethylene |

| Insulation OD: | 2.13 ± 0.15 mm |

| Fire Barrier | Mica tape (Option) |

| Conductor Color Code: | White X Blue, White X Orange, White X Green, White X Brown |

| Foil shield: | Aluminum/Polyester Foil |

| Braid: | Tinned copper wire |

| Braid Coverage: | ≥80% |

| Outer jacket: | LSZH SHF1 |

| Outer Jacket OD: | 7.0 ± 0.20 mm for 1 pair, 10.5 ± 0.20 mm for 2 Pairs, 11.5 ± 0.20 mm for 4 pairs |

| Outer Jacket Color: | Purple (optional) |

Our commission should be to provide our customers and consumers with ideal top quality and aggressive portable digital products for China Manufacturer for Marine Engine Push Pull Control Cable, We warmly welcome consumers, company associations and buddies from all over the planet to speak to us and find cooperation for mutual advantages.

China Manufacturer for China Electronic Wire Harness and High Quality Custom Cable Assembly, In order to make more people know our goods and to enlarge our market, now we have devoted a lot of attention to technical innovations and improvement, as well as replacement of equipment. Last but not the least, we also pay more attention to training our managerial personnel, technicians and workers in planned way.

| Halogen acid gas, Degree of acidity of gases: | IEC 60754-1/2 |

| Jacket, Insulation material: | IEC 60092-360 |

| Smoke Emission: | IEC 61034-1/2 |

| Flame retardant: | IEC 60332-3-22 |

| Fire resistant: | IEC 60331-23 |

| UV resistant: | UL1581 |

| Impedance: | 120 Ω |

| DC Resistance: | 55 Ω/Km max. @ 20°C |

| Capacitance: | 35.0 PF/m |

| Resistance unbalance: | ≤5% |

| Voltage Rating: | 300 V |

| Operating Temperature: | -30°C~75°C |

| UV Resistance: | Yes |

| Frequency (MHz) | 1 | 10 | 100 | 200 | 500 | 1000 |

| Pairs | 1pair | 1pair | 2pairs, 4pairs | |||

| Attenuation dB/100m (Nom.) | 1.7 | 5.0 | 0.55 | 0.80 | 1.2 | 1.8 |